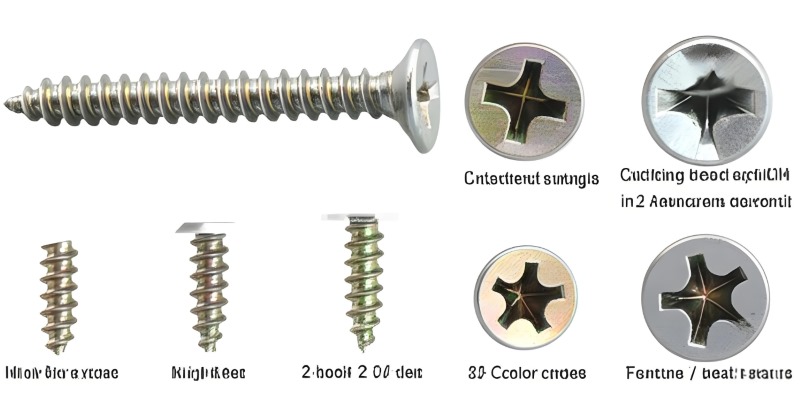

Color-coated screws have quickly become a preferred fastening solution for professionals and DIYers alike across the USA. Their versatility, durability, and aesthetic appeal make them ideal for a wide range of applications—from securing metal roofing panels to adding the perfect finishing touch in interior design projects. Whether you’re tackling an outdoor build or a stylish home renovation, color-coated screws combine strength with seamless style.

🏠 Strong Enough for Roofing, Subtle Enough for Interiors

In construction, the little details matter. Color-coated screws are engineered to not only hold strong under pressure but also blend into their surroundings. Available in a variety of shades to match roofing, siding, and trim materials, they offer the best of both worlds: functionality and appearance.

Ideal uses include:

-

Metal roofing and wall panel fastening

-

Gutter installation and flashing

-

Outdoor furniture and fencing

-

Cabinetry, shelving, and accent wall installations

-

Decorative wood or metal interior features

Their color-matching ability reduces the need for touch-ups and improves the overall visual finish.

🛠️ Built to Withstand the Elements

Color-coated screws aren’t just about looks—they’re made to last. High-performance coatings resist:

-

Corrosion and rust, even in coastal or high-moisture areas

-

UV degradation, preserving color integrity over time

-

Friction wear, maintaining a clean, consistent finish

This makes them ideal for both interior and exterior projects where durability is non-negotiable.

🎨 Aesthetic Flexibility for Design-Focused Projects

From architects to interior designers, many professionals turn to color-coated screws to maintain visual continuity. By matching fasteners to surface materials—metal, wood, or composites—designers can enhance sleek lines and avoid visible distractions.

Available in matte, gloss, and textured finishes, they add polish to any project, especially in:

-

Retail spaces

-

Home décor installations

-

Office build-outs

-

Exhibition stands and art displays

They allow for secure fastening without compromising the final look.

🔧 Efficient, Professional, and Cost-Effective

Installing color-coated screws is as simple as standard fasteners but with a more refined outcome. Bulk availability, compatibility with standard tools, and long-term reliability make them a cost-effective upgrade for construction crews and contractors aiming for professional results.

🌟 Why Choose CHE Precision Group?

CHE Precision Group is a trusted leader in manufacturing high-quality color-coated screws designed for a wide range of applications. We combine precise engineering with industry-grade coatings to ensure our screws deliver superior performance and aesthetic value—no matter where they’re used.

Why CHE?

-

Wide color selection to match any project

-

Rust- and fade-resistant coatings

-

Strict quality control for consistent performance

-

Custom solutions available for bulk and specialty orders

Contact us today to explore how CHE Precision Group can support your next build—inside and out—with durable, design-friendly fastening solutions.