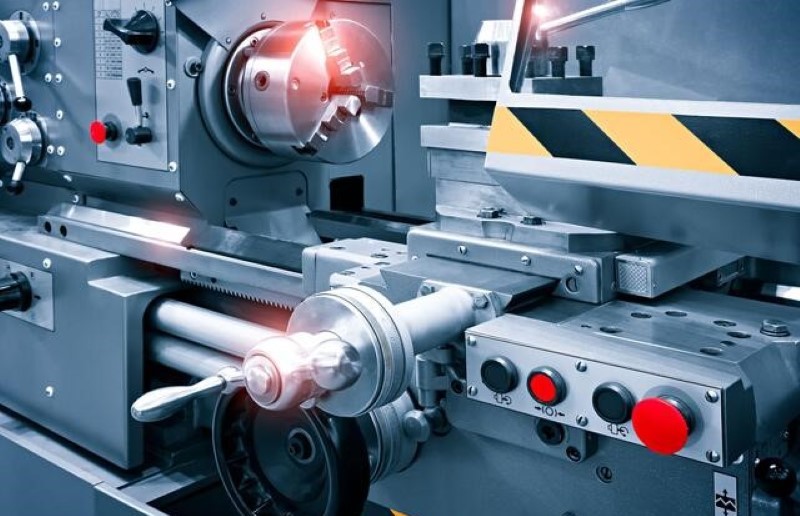

Stainless steel CNC parts are the cornerstone of modern manufacturing, where high strength, corrosion resistance, and dimensional accuracy are non-negotiable. Whether used in aerospace, medical devices, automotive systems, or industrial equipment, steel CNC parts offer the ultimate combination of form and function. Precision-machined to exact specifications, these components ensure reliability and long-term performance, even in the most demanding environments.

🛠️ What Are Stainless Steel CNC Parts?

Stainless steel CNC parts are components manufactured using Computer Numerical Control (CNC) machining processes. They are cut, drilled, milled, or turned from high-grade stainless steel bars or sheets using automated machinery that ensures extreme precision and repeatability.

Key characteristics include:

-

Exceptional corrosion and wear resistance

-

High tensile strength and hardness

-

Tight tolerances down to ±0.01mm

-

Excellent surface finish and complex geometry capability

-

Compatible with CNC turning, الطحن, drilling, and grinding

Common stainless steel grades include 303, 304, 316, and 17-4PH, depending on application requirements.

🚗 Where Stainless Steel CNC Parts Excel

Due to their performance properties, stainless steel CNC parts are widely used in:

-

Medical equipment – Surgical tools, implant components, and housings

-

السيارات – Engine parts, gear housings, fuel system fittings

-

الفضاء – Structural brackets, fasteners, and sensor enclosures

-

Industrial machinery – Shafts, bushings, couplings, and valves

-

Consumer electronics – Durable frames, mounts, and precision connectors

These parts ensure long-lasting performance and low maintenance in high-stress environments.

⚙️ Advantages of CNC-Machined Stainless Steel Components

When choosing stainless steel CNC parts, you benefit from:

-

✅ Unmatched precision – Ideal for tight-tolerance applications

-

✅ Superior surface finish – Suitable for both functional and aesthetic roles

-

✅ High repeatability – Consistent output in mass production

-

✅ Customizability – Easily adapted for prototype or low-volume runs

-

✅ Strong resistance to rust, acids, heat, and mechanical wear

CNC machining allows for innovation without compromising strength or consistency.

🌍 Built for Harsh Environments and Critical Roles

Stainless steel’s natural properties make CNC-machined components suitable for extreme conditions:

-

Temperature resistance in engines and exhaust systems

-

Sterilization-ready surfaces for food and medical use

-

Chemical resistance for oil & gas, marine, and laboratory applications

-

Longevity in outdoor, high-humidity, or abrasive settings

Their resilience leads to reduced downtime, fewer replacements, and higher ROI.

🌟 Why Choose CHE Precision Group?

At CHE Precision Group, we combine decades of experience with advanced CNC machining technology to deliver high-precision stainless steel CNC parts that meet global quality standards. From prototyping to high-volume production, we serve industries that demand excellence in every detail.

Why CHE Precision Group?

-

State-of-the-art multi-axis CNC machining centers

-

Expertise in stainless steel and exotic alloy materials

-

Full in-house capabilities: CAD/CAM, machining, inspection, finishing

-

ISO-certified quality management and strict tolerance control

-

Custom OEM/ODM solutions with fast lead times

اتصل بنا today to learn how CHE Precision Group can support your next project with steel CNC parts that embody precision, durability, and unmatched performance—built to your specs, delivered with excellence.