CNC parts processing lies at the core of modern industrial innovation. From aerospace to automotive, medical devices to robotics, this cutting-edge machining method delivers the precision and reliability that complex components demand. As industries push boundaries in design and function, CNC parts processing becomes not only a method but a strategic advantage.

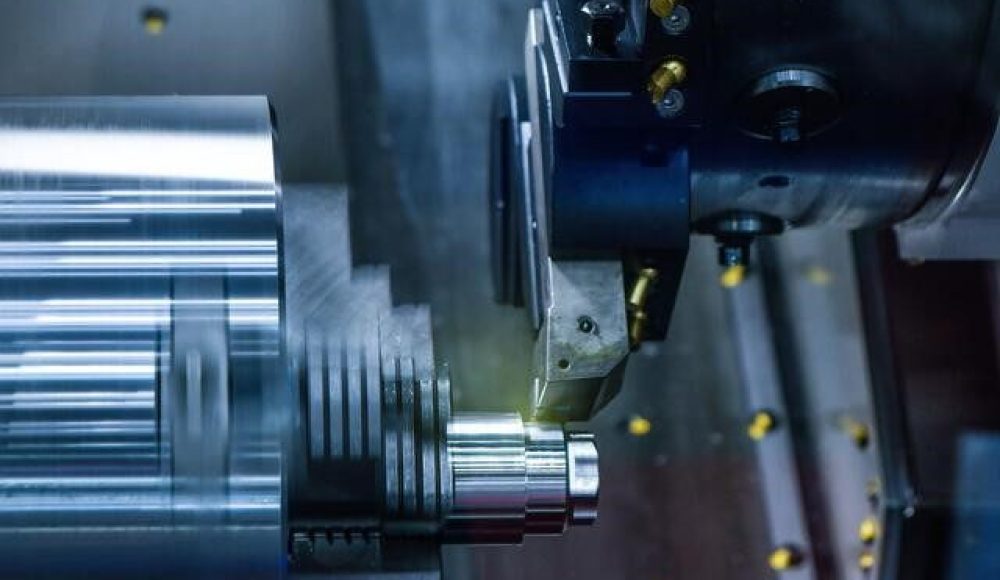

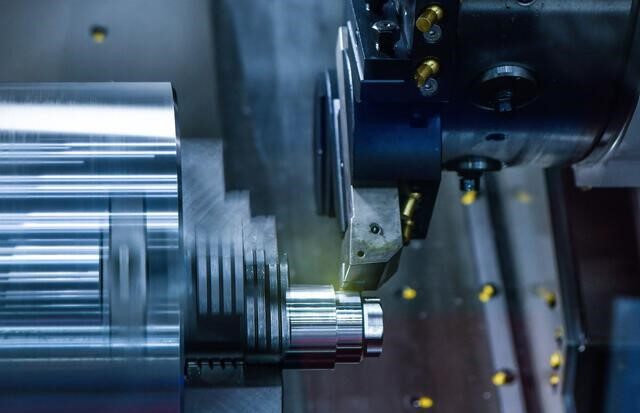

Using advanced computer numerical control systems, CNC machines execute highly complex cuts, drills, and turns with sub-millimeter accuracy. The result? Flawless parts are produced faster, more consistently, and with less human error.

🏭 What is CNC Parts Processing?

CNC parts processing refers to the automated machining of components using pre-programmed software to control the movement of factory tools and machinery. Whether it’s aluminum, titanium, stainless steel, or engineering plastics, CNC processes can create high-precision parts at scale, reliably and repeatedly.

It’s a manufacturing solution trusted by engineers and OEMs worldwide for its unmatched accuracy, tight tolerances, and capacity for mass production.

🔍 Why Precision Matters

In industries where performance and safety are non-negotiable, the precision of CNC parts processing makes all the difference. Complex geometries, tight tolerance fits, and multi-axis operations are standard in high-tech manufacturing, and only CNC processing can deliver such performance with efficiency.

For applications like medical implants or aerospace brackets, even a fraction of a millimeter can determine success or failure. That’s why CNC parts processing is the go-to choice when failure is not an option.

🚀 Driving Innovation and Efficiency

With the integration of AI, digital twins, and smart automation, CNC parts are evolving. Today’s systems offer real-time feedback, predictive maintenance, and ultra-fast production cycles. This not only reduces costs but also speeds up time-to-market, giving manufacturers a competitive edge in a fast-moving world.

Furthermore, multi-axis machines and hybrid technologies (like CNC + 3D printing) are pushing innovation forward, enabling new designs and material combinations previously thought impossible.

🌱 Sustainable and Scalable Production

Beyond precision, modern CNC parts processing also contributes to sustainability. Efficient toolpaths and material-saving strategies minimize waste, while clean-cutting fluids and automation reduce environmental impact. It’s a scalable, eco-conscious approach to manufacturing without compromising quality.

🌟 Why Choose CHE Precision Group?

At CHE Precision Group, we specialize in delivering high-precision CNC parts processing solutions tailored to your industry needs. With advanced facilities, experienced engineers, and a commitment to excellence, we support everything from prototyping to full-scale production.

Whether you require tight-tolerance components or complex custom parts, please contact us. We’re ready to turn your designs into durable, high-performance realities—faster and more cost-effectively than ever before.