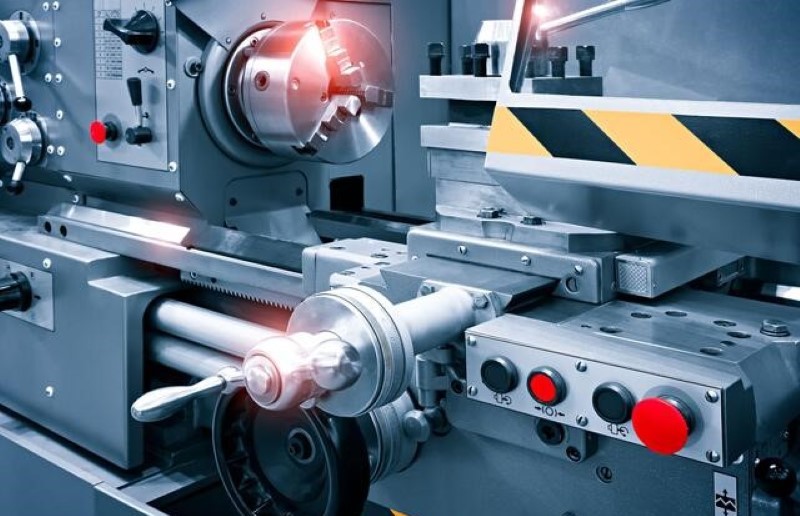

Stainless steel CNC parts are the cornerstone of modern manufacturing, where high strength, corrosion resistance, and dimensional accuracy are non-negotiable. Whether used in aerospace, medical devices, automotive systems, or industrial equipment, steel CNC parts offer the ultimate combination of form and function. Precision-machined to exact specifications, these components ensure reliability and long-term performance, even in the most demanding environments.

🛠️ What Are Stainless Steel CNC Parts?

Stainless steel CNC parts are components manufactured using Computer Numerical Control (CNC) machining processes. They are cut, drilled, milled, or turned from high-grade stainless steel bars or sheets using automated machinery that ensures extreme precision and repeatability.

Key characteristics include:

-

Exceptional corrosion and wear resistance

-

High tensile strength and hardness

-

Tight tolerances down to ±0.01mm

-

Excellent surface finish and complex geometry capability

-

Compatible with CNC turning, moagem, drilling, and grinding

Common stainless steel grades include 303, 304, 316, and 17-4PH, depending on application requirements.

🚗 Where Stainless Steel CNC Parts Excel

Due to their performance properties, stainless steel CNC parts are widely used in:

-

Medical equipment – Surgical tools, implant components, and housings

-

Automotivo – Engine parts, gear housings, fuel system fittings

-

Aeroespacial – Structural brackets, fasteners, and sensor enclosures

-

Industrial machinery – Shafts, bushings, couplings, and valves

-

Consumer electronics – Durable frames, mounts, and precision connectors

These parts ensure long-lasting performance and low maintenance in high-stress environments.

⚙️ Advantages of CNC-Machined Stainless Steel Components

When choosing stainless steel CNC parts, you benefit from:

-

✅ Unmatched precision – Ideal for tight-tolerance applications

-

✅ Superior surface finish – Suitable for both functional and aesthetic roles

-

✅ High repeatability – Consistent output in mass production

-

✅ Customizability – Easily adapted for prototype or low-volume runs

-

✅ Strong resistance to rust, acids, heat, and mechanical wear

CNC machining allows for innovation without compromising strength or consistency.

🌍 Built for Harsh Environments and Critical Roles

Stainless steel’s natural properties make CNC-machined components suitable for extreme conditions:

-

Temperature resistance in engines and exhaust systems

-

Sterilization-ready surfaces for food and medical use

-

Chemical resistance for oil & gas, marine, and laboratory applications

-

Longevity in outdoor, high-humidity, or abrasive settings

Their resilience leads to reduced downtime, fewer replacements, and higher ROI.

🌟 Why Choose CHE Precision Group?

No Que grupo de precisão, we combine decades of experience with advanced CNC machining technology to deliver high-precision stainless steel CNC parts that meet global quality standards. From prototyping to high-volume production, we serve industries that demand excellence in every detail.

Why CHE Precision Group?

-

State-of-the-art multi-axis CNC machining centers

-

Expertise in stainless steel and exotic alloy materials

-

Full in-house capabilities: CAD/CAM, machining, inspection, finishing

-

ISO-certified quality management and strict tolerance control

-

Custom OEM/ODM solutions with fast lead times

Contate-nos today to learn how CHE Precision Group can support your next project with steel CNC parts that embody precision, durabilidade, and unmatched performance—built to your specs, delivered with excellence.